0 items

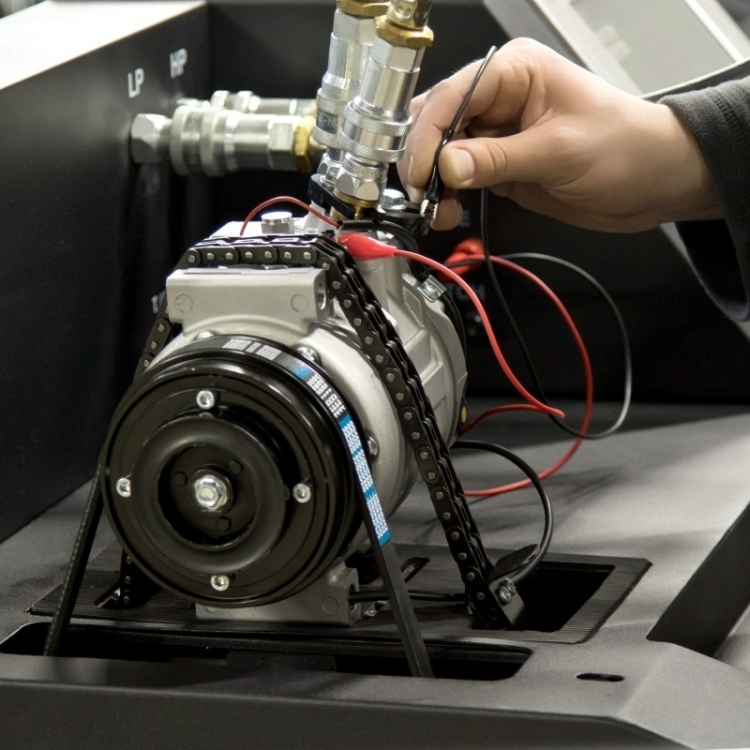

AC Testing stand * / MS111

MS111 – Test bench for AC compressors

https://youtu.be/79EX213RvjQ

https://youtu.be/-rnkTpYL8wQ

https://youtu.be/1V2Hvlpvou0

Duomenų apsauga

Duomenų apsauga

Jūsų duomenys griežtai tvarkomi pagal Duomenų apsaugos reglamentą.

Pristatymo informacija

Pristatymo informacija

Pristatymas per 1-3 darbo dienas

Grąžinimo taisyklės

Grąžinimo taisyklės

Pas mus taikomas standartinis prekių grąžinimas (14 kalendorinių dienų)

The test bench is intended to test AC compressors of wide range of vehicles on R134a refrigerant. The equipment detects failures of a vehicle unit before its mounting in a car, whether it is a remanufactured, repaired unit or a used one. In the process of testing, data is shown on LCD display. It gives an opportunity to follow testing results realtime, save and/or print them due to software special features. Unit fixation mechanism is very flexible: a compressor can be easily fixed, no matter what kind of fittings it has. Units with electromagnetic clutch or electromagnetic valve can be tested both separately and simultaneously. Peculiar features of electric commutation are considered, connection polarity is identified automatically, indicator on the control panel indicates on presence of a diode in a circuit. Features:

- meets the latest requirements of contemporary service centers

- simulates real operation in a car

- tests AC compressors before and after their renovation

- fixes temperature generated by the compressor

- all testing data is shown on LCD display

- possesses an option to follow testing results realtime

- detects mechanical (knock, vibration) and visual failures (supply and suction pressure)

- electromagnetic valve control from 0% to 100%

- has a function to save and/or print testing results thanks to special software features

- control of load on a tested unit

- drive rotation reverse

- filter replacement signal indicator

- condenser fan control

- HP pressure setting for testing of a unit

- software update possibility

- easy-to-use operation

- quick testing procedure

- long-lasting service

- safety and reliability

- 1 year warranty

The equipment set includes:

- test bench

- set of changeable fittings to connect the compressor to the test bench hydraulic system

- hydraulic hoses to connect the unit to the test bench hydraulic system

- crocodile clip cable to connect the electromagnetic clutch and valve

- Wi-Fi adapter

- refrigerant fine filter (1 μm²)

- solenoid filter

- HP and LP quick-disconnect couplings

- filter rubber gaskets 4,5×135 mm

- clamp bars for changeable fittings

- door key

- user manual

|

Weight, kg |

180 |

|

Dimensions, (L×W×H), mm |

900х560х1250 |

|

Supply voltage, V |

380 |

|

Drive power, kW |

5,5 |

|

Drive speed adjustment |

Smoothly/ gradually |

|

Drive speed, rpm |

0-3000 |

|

Supply type |

Three-phase (3L+N+PE) |

|

Refrigerant amount in the system, g |

1100 |

|

Refrigerant filtration |

Yes, 1micron*2 |

|

Utilized refrigeran |

R134a |

|

Test bench filling |

Cylinder with refrigerant or filling system |

|

Unit line vacuum |

Yes |

|

Unit regrigerant pumping |

Yes |

|

Type of measuring sensors |

Electronic |

|

Drive type |

Belt, V- belt / poly-V belt |

|

Connection to the Internet |

Wi-Fi (802.11 a/b/g/ac) |

|

Data printout |

Yes |

|

Display parameters |

HP, bar; LP, bar; Unit t, °С; Epr t, °С; PWM; RPM |

|

Data display |

10,4” LCD display |

|

Type of filling fittings |

Automotive HP and LP |

|

Oil amount in the system, g |

200 |

|

Utilized oil |

PAG100 |

Review

No customer reviews for the moment.